Parker Lord

Covermat Partners with Parker LORD to Bring Advanced Electronics Solutions to Thailand Covermat is now the distributor of Parker LORD. This partnership offers Thai businesses access to;

- CoolTherm® Solution : CoolTherm solutions to prevent overheating and ensure reliability.

- Assembly & Bonding : assembly process and ensure the long-term reliability of electronic components and devices.

PRODUCTS & SERVICE

CoolTherm® Materials Solution

Focus: Preventing overheating, ensuring reliability in hot climates

Key Series:

- Gap Fillers

- Adhesive

- Encapsulants

- Gels & Grease

Protect components and improve stability

To extend the life of your power electronics, you need to maintain low thermal resistance and protect components from shock, moisture and debris.

CoolTherm® low viscosity, highly thermally conductive pottants provide a robust thermal interface, as well as protect delicate electrical components

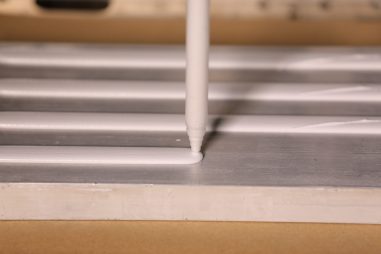

GAP FILLERS

Get the best performance out of your batteries by filling in surface imperfections with a thermally conductive gap filler. They are a stay- in-place solution and cure as a gel, easing the stresses caused by thermal differences and flex. Low Outgas Options: We offer low ppm siloxane solutions for sensitive electronic applications. Protect Against Shock: Our gap fillers remain tacky and soft to dampen vibration.

-

Low Outgas Options:

We offer low ppm siloxane solutions for sensitive electronic applications. -

Protect Against Shock:

Our gap fillers remain tacky and soft to dampen vibration.

ADHESIVES

Formulated for standard MMD equipment, our adhesives provide your application with structural integrity. Our thermally conductive adhesives not only provide mechanical rigidity but also a thermal connection where heat is a problem.

-

Improve Design Flexibility:

No longer constrained by mechanical fixtures and given the ability to bond a wide variety of substrates, you are free to discover the possibilities -

Reduce Complexity:

Reduce the need for fasteners, thereby simplifying your battery pack design.

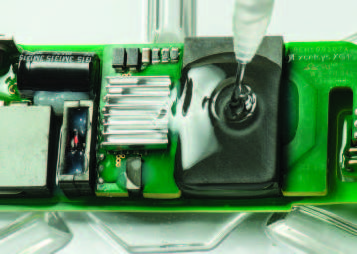

ENCAPSULATESE

Thermally connect your cells to the heat sink by encapsulating the entire pack and minimize design gaps by taking advantage of high dielectric strength.

-

Improve Performance:

Our encapsulants facilitate optimum heat transfer because of their high thermal conductivity and low viscosity. -

Protect Electronics:

Potting and encapsulants provide protection from dust and moisture and can reduce vibration. -

Protect Electronics:

Parker LORD encapsulants exhibit low shrinkage upon curing.

GELS & GREASES

Our experts understand that different applications require different solutions. We offer a broad portfolio of gels and greases to meet your unique specifications.

-

Resist Pump-Out:

Parker LORD gels enhance stable thermal performance by resisting pump-out. -

Protect Against Shock:

Our thermal interface materials provide excellent isolation and vibration dampening.

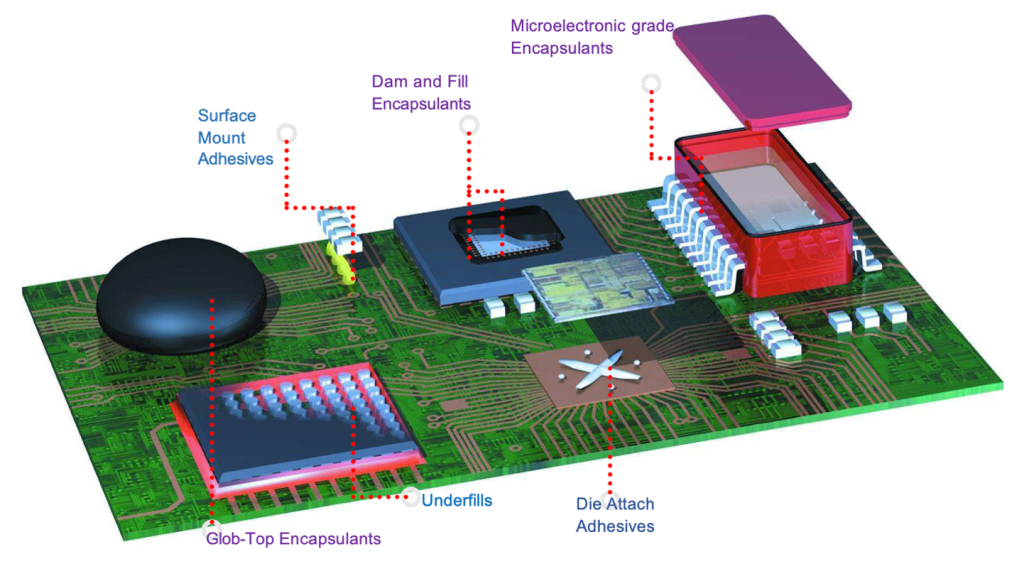

Assembly & Bonding Solution

Focus: Assembly process and ensure the long-term reliability of electronic components and devices.

Key Series:

- Die Attach Adhesives

- Surface Mount Adhesives

- Board-Level Encapsulants

- Underfill Products

Benefits:

- Enhanced Protection: Shields electronics from moisture, dust, chemicals, and mechanical stress.

- Improved Reliability: Increases component lifespan and reduces failures due to environmental factors.

- Enhanced Thermal Management: Some encapsulants and underfills offer thermal conductivity to improve heat dissipation.

Die Attach Adhesives

- Securely bond semiconductor dies to substrates for optimal electrical and thermal performance. Key products: MD-130 (Electrically conductive adhesive) and other high-reliability options.

- Key products: MD-130 (Electrically conductive adhesive) and other high-reliability options.

Surface Mount Adhesives (SMAs)

- Provide reliable attachment of surface mount components to printed circuit boards (PCBs).

- Provide reliable attachment of surface mount components to printed circuit boards (PCBs).

Board-Level Encapsulants

- Encapsulate entire PCBs or modules to protect against moisture, dust, chemicals, and mechanical shock.

-

Glob Top : Over Molding Dam & Fill :

a Pair 2 products used together to encapsulate Dam materials ME-456, high viscosity/Thicxo, build a dam around the chip, fill ME-455, low viscosity fill in the cavity. 2 Materials have same anhydride chemistry, and co cure together.

- Dam materials ME-456, high viscosity/Thicxo, build a dam around the chip, fill ME-455, low viscosity fill in the cavity.

- 2 Materials have same anhydride chemistry, and co cure together.

Underfill Products

- Fill gaps under components like ball grid arrays (BGAs) and chip scale packages (CSPs) to enhance mechanical strength and reliability. Protect against thermal cycling stresses and improve solder joint fatigue life.

- Needle Dispensing

- Jetting

- Substrate and/or needle heating required

- Optimum dispensing pattern may need to developed