What is LIMEX

LIMEX is a new material mainly made from limestone that can become an alternative to plastic and paper.

Earth, a Planet of Stones.

Limestone, which is the raw material of LIMEX is a resource that can be self-sufficient globally, where resources are scarce. The estimated recoverable years of limestone continue to grow, with 24 billion tons of resources reserved in Japan alone, and limestone is said to be a resource with a very low risk of depletion compared to oil, water, and forest resources. Since paper alternative products can be manufactured with almost no use of water or forest, it could be manufactured in many places. Also, by promoting local production for local consumption, a compact supply chain can be constructed, which could reduce impact on the environment. Because it is a resource that is abundant everywhere, we believe it can save the world globally.

Limestone deposit

Japan

Korea

India

China

Taiwan

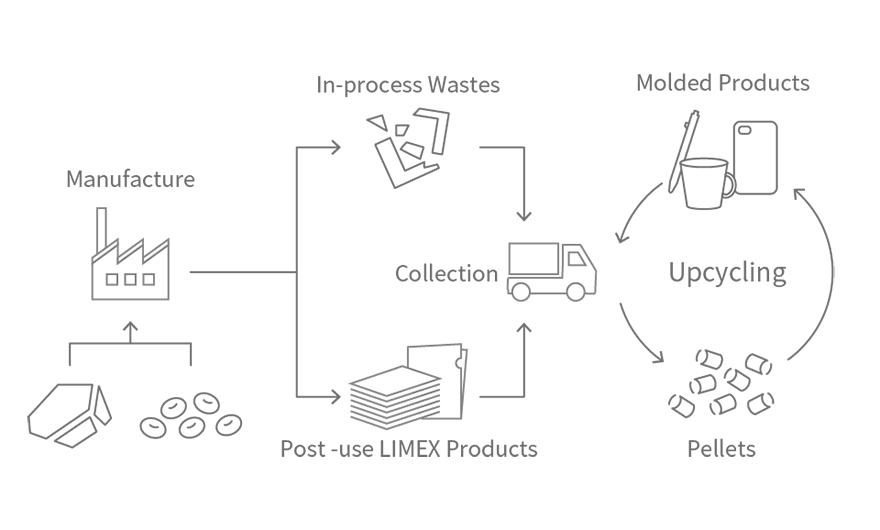

Compared to polypropylene, which is a petroleum-based resin, LIMEX has been proved to be a material with a lower rate of deterioration of physical properties and higher recycling efficiency than PP in terms of melt flow rate (MFR) *1 and Charpy impact strength*2. In addition, when we verified the sorting of LIMEX and PP with an optical sorter, we were able to detect them as different substances and prove that they can be derived. the collected post-consumer LIMEX products (paper alternative products) will be upcycled into plastic alternative products. TBM will promote the resource recycling of LIMEX by cooperating with domestic and overseas partner companies.

*1 MFR: A numerical value that represents the fluidity of a thermoplastic resin when it is melted

*2 Charpy impact strength: Impact test to evaluate the energy required to break the test piece and the toughness of the test piece

International Patents for LIMEX.

In 2014, LIMEX was patented in Japan. The basic patent has been submitted in over 40 countries worldwide by TBM Co., Ltd.

LIMEX has been introduced at international conferences, such as COP and G20.

Moreover, it is registered in the sustainable technology dissemination platform of

UNIDO (United Nations Industrial Development Organization) as an excellent technology of Japan.

Flexible molding using LIMEX.

LIMEX is suitable for diverse molding methods including injection molding, extrusion molding, vacuum molding, and blow molding. Though LIMEX is a composite material, it does not require custom equipment and can be processed using traditional methods and machinery. LIMEX is used by more than 6,000 companies and municipalities for a variety of purposes. (As of June 2021)

LIMEX Pellets

LIMEX, which uses limestone as the main raw material,

is a material that can create injection molded products, vacuum formed products,

and inflation molded products with existing equipment.

Benefits of LIMEX Pellets

The first advantage is that the amount of petroleum used can be significantly reduced compared to conventional plastics made from petroleum. Therefore, it can contribute to the conservation of limited petroleum resources and contribute to CO2 reduction. The second advantage is that limestone, has less price fluctuations than plastic, so it can be offered at a stable price.

LIMEX Bag

LIMEX bag 2

LIMEX Clothes hanger

LIMEX Cup

LIMEX Food Container

HPM

(High Performance Masterbatch)

- Increase of CaCO3 volume without Performance Degradation

- Reduction of expensive Petroleum based resin volume.

LIMEX Sheets

LIMEX Sheet, which is mainly made of limestone, is a material that can be used as an alternative for paper. Compared to paper, LIMEX Sheet does not use any wood pulp during manufacturing and requires almost no water. It has high durability and water resistance and can be used indoors and outdoors.

Benefits of LIMEX Sheet

The first advantage is that the burden on the environment can be reduced. Until now, there have been two major materials used as paper: paper made from wood pulp and synthetic paper made from petroleum-derived resin. Since wood pulp uses wood as a raw material and requires a large amount of water in the manufacturing process, various discussions have been held from the viewpoint of environmental protection and resource protection. Synthetic paper, on the other hand, has the advantage of being significantly superior to paper in terms of water resistance and durability, but since it is dominated by petroleum components, there are concerns about its impact on the increase in CO2 emissions. Unlike conventional paper and synthetic paper, LIMEX Sheet requires almost no wood or water and contains 50% or more of inorganic substances including limestone, which can contribute to the reduction of the amount of petroleum-derived resin used.

The second advantage is high durability and water resistance. Normally, paper is laminated to make it water resistant, but because LIMEX Sheet is water resistant, it can be used in places where it might get wet. In addition, it has excellent durability, is harder to tear than paper and can be used outdoors.

LIMEX Booklet

LIMEX Box

LIMEX Business Card

LIMEX Folder

LIMEX Poster

LIMEX Price Tag