INEOS Styrolution is the leading, global styrenics supplier with a focus on styrene monomer, polystyrene, ABS Standard and styrenic specialties. With world-class production facilities and more than 90 years of experience, INEOS Styrolution helps its customers succeed by offering the best possible solution, designed to give them a competitive edge in their markets.

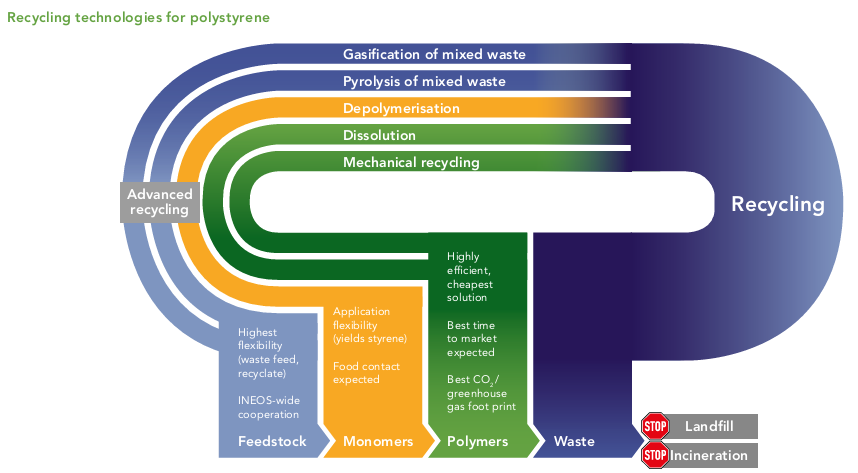

Polystyrene is not only a versatile, aesthetic, and durable material, it is also one of the most recyclable polymers. It is one of the best sortable plastics in the waste stream, its barrier properties block possible contaminants, and its ideal ceiling temperature allows it to be depolymerised. These unique properties allow it to be recycled using several different technologies from mechanical recycling and dissolution to advanced recycling methods such as depolymerisation, pyrolysis and gasification.

These technologies offer recycled polystyrene matching virgin quality with no sacrifice in properties, thus enabling food-contact applications and nearly infinite recycling cycles. Therefore, we are working on different technologies in parallel to reach the recycling quota for polystyrene and offer this recycled material to our customers by 2025.

A DECADE OF EVOLUTION LEADING TO A CIRCULAR AND LOW-CARBON ECONOMY FOR STYRENICS

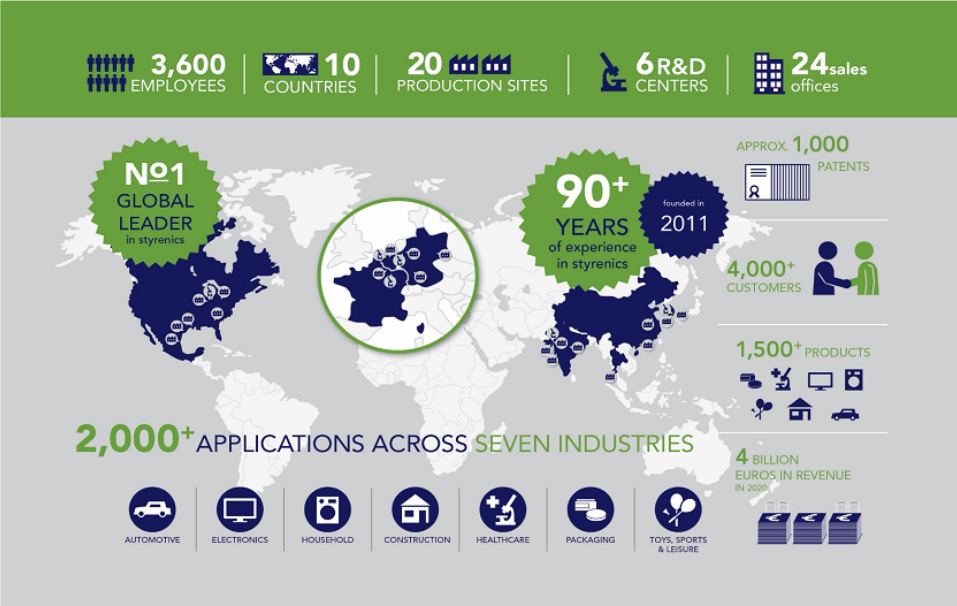

At a glance

- Global leader: No. 1 with focus on Styrene Monomer, Polystyrene, ABS Standard and Styrenic Specialties

- Employees: 3,600 worldwide

- Production sites: 20 manufacturing sites in 10 countries

- Customer base: Customers in 106 countries

- Sales: 6 billion EUR in 2021

INEOS Styrolution ECO

INEOS Products

Styrolux® ECO (SBC)

Styrolux® ECO resins are a range of thermoplastic styrene-butadiene copolymers (SBC). One of the outstanding characteristics of Styrolux ECO copolymers is their combination of high transparency, brilliance and impact resistance. The good miscibility of Styrolux ECO and polystyrene allows adjustment to the desired toughness, while at the same time reducing material costs. Styrolux ECO can be extruded, thermoformed and injection moulded into a variety of high-quality products.

Styrolux® ECO is made using renewable feedstock, based on a mass balance process certified by ISCC PLUS. Styrolux ECO is available with a renewable content of min. 60%. This results in a carbon footprint reduction of 74% to 85% compared to fossil-based Styrolux.Styrolux ECO’s feedstock sources, supply chain and production processes have been awarded ISCC PLUS certification and comply with the highest sustainability certification criteria.

Styroflex® ECO (SBC)

Styroflex® ECO is a styrene-butadiene block copolymer (SBC) with the properties of a thermoplastic elastomer (S-TPE), suitable for extrusion (including both blown and cast film) and injection moulding. Characterized by a combination of high resilience and toughness, optical clarity and process stability, Styroflex ECO offers as well a good printability and good adhesion to many different polymers. In film applications, Styroflex ECO provides excellent stretch recovery, superior transparency and puncture resistance, high oxygen and moisture permeability. It is also employed as a high performance additive to increase toughness and e.g. stress cracking resistance of styrenic and olefinic polymers.

Styroflex® ECO is made using renewable feedstock, based on a mass balance process certified by ISCC PLUS. Styroflex ECO is available with a renewable content of min. 60%. This results in a carbon footprint reduction of 75% compared to fossil-based Styroflex.

Luran® ECO (SAN)

Luran® ECO is a styrene acrylonitrile copolymer (SAN) featuring a well-balanced property profile ranging from good transparency and excellent chemical resistance to high stiffness, extraordinary heat resistance as well as very good dimensional stability. The portfolio comprises a broad selection of grades designed for injection moulding and extrusion applications. It is an ideal solution for a variety of products, such as durable household goods and cosmetics packaging.

Luran ECO is made using renewable feedstock, based on a mass balance process certified by ISCC PLUS. Luran ECO is available with a renewable content of min. 60%. This results in a carbon footprint reduction of 77% to 99% compared to fossil-based Luran®.

NAS® ECO (SMMA)

NAS® ECO is a stiff, amorphous styrene methyl methacrylate (SMMA) copolymer for demanding applications requiring excellent transparency such as water tanks, displays, food containers or boxes. It features an outstanding water-clear appearance, an extreme low haze as well as a good thermal and chemical resistance. The optical properties of NAS® ECO are on a similar level as PMMA, while NAS ECO has a density and processing advantage compared to acrylic solutions.

NAS ECO is made using renewable feedstock, based on a mass balance process certified by ISCC PLUS. NAS ECO is available with a renewable content of min. 70%. This results in a carbon footprint reduction of 79% to 93% compared to fossil-based NAS.